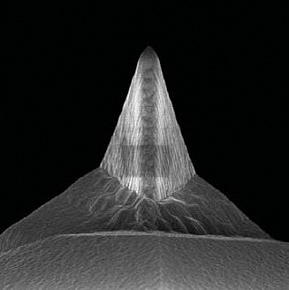

Unique probes with Single Crystal Diamond tip specially designed for Nanoindentation, Nanoscratching, Lithography etc. Resonant frequency 500-1000kHz, force constant 100-600 N/m, typical curvature radius 10nm.

These tips are specifically designed for high mechanical loads and scratch testing applications. By using wear-resistant diamond and a board cone angle the contact size is well characterized and stays constant during repeated mechanical measurements. These probes have demonstrated highly repeatable deep (~100nm) indentations into materials such as fused silica and are able to image the indents at high resolution in-situ using the same probe. A gold reflex coating deposited on the detector side of the cantilever to enhance the reflectance of the laser beam.

The probes ideally suited to scratch testing and long period probe lifetime applications where quantitative nanomechanics are not essential.

Nominal values: force constant - 350 N/m, resonance frequency – 750 kHz.

Cantilever specifications

|

Geometry:

|

Rectangular

|

|

Material:

|

Diamond coated Si

|

|

Cantilever bending:

|

< 3°

|

Bulk tip specifications

|

Si geometry:

|

4 Sided Pyramid

|

|

Si tip height (h):

|

12,5 ± 2.5 μm

|

|

Front angle:

|

25 ± 5°

|

|

Back angle:

|

15 ± 5°

|

|

Side angle:

|

22.5 ± 5°

|

|

Tip offset:

|

15 ± 5 μm

|

Single crystal diamond tip specifications

|

Geometry:

|

Cone

|

|

Tip radius:

|

10 ± 5 nm

|

|

Tip height (h):

|

500 nm ± 100 nm

|

|

Tilt angle:

|

0 ± 1°

|

|

Tip material:

|

Diamond

|

|

Cone ½ angle:

|

45 ± 3°

|